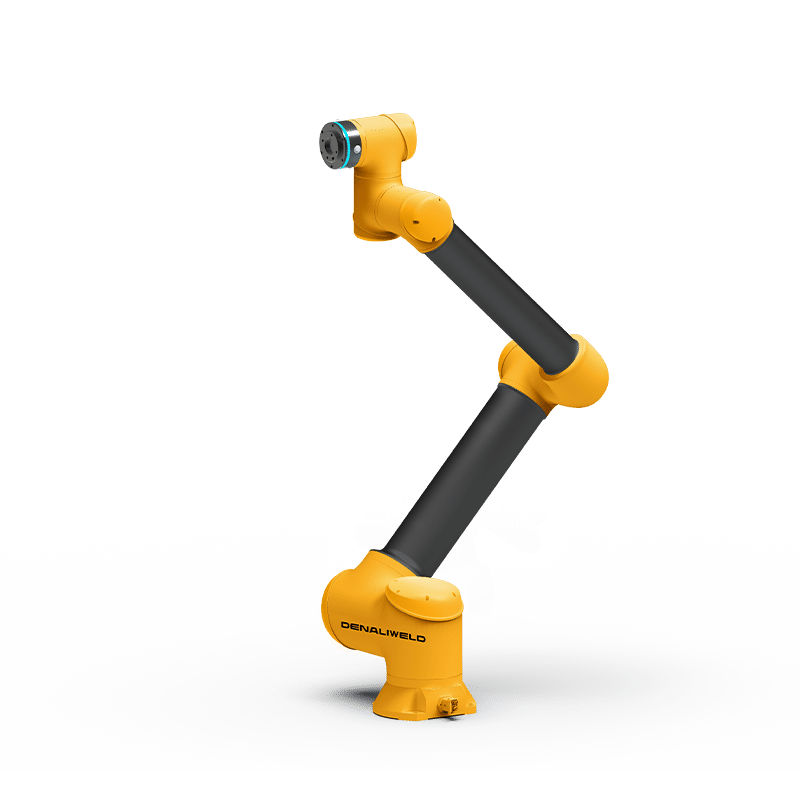

Cobot Series

$39,999.00

Modular design

One-touch switching for manual/automatic welding

Compatible with most robotic systems

DenaliWeld COBOT Welding System

The DenaliWeld COBOT Welding System combines advanced automation with user-friendly technology, delivering precision, efficiency, and seamless integration for modern manufacturing environments.

- Independently developed: Our independently developed welding robots and welding control systems are compatible with both air-cooled and water-cooled Denaliweld models, providing flexible integration across multiple platforms.

- Modular Design for Easy Maintenance: Engineered for uncomplicated maintenance and quick repairs, reducing downtime and increasing productivity.

- Intelligent Cobot Programs: Features a simple user interface with pre-set parameters for one-click operation, making it easy for operators to achieve consistent and precise results.

- Welding Data Acquisition System: Monitors and records welding performance, assisting in operation tracking and cost calculations for optimized workflows.

- Seamless Automation Integration: With one-click switching, easily transition between Cobot and robot automation using the DENALIWELD ROBOX™

- Wide Compatibility: DENALIWELD welding machines are compatible with most leading Cobot manufacturers, ensuring versatility in industrial applications.

- Advanced Automatic Welding Head: Utilizing the Automatic Welding Head (GCR 5/10/16)enables real-time power adjustments throughout the welding process for enhanced precision and quality.

- Optional Seam Tracking System: Available with an optional seam tracking system, allowing for precise weld alignment and improved accuracy.

Features and Configuration

DenaliWeld Collaborative Robots (Cobots) are designed to deliver precision, efficiency, and ease of use, providing a cost-effective solution to elevate your welding operations. With their lightweight, flexible, and intelligent design, these cobots offer best-in-class performance to meet the demands of modern manufacturing.

- Lightweight and Flexible Design: Easy to integrate into various production lines, providing versatile welding solutions for a wide range of applications.

Intelligent and User-Friendly Operation: Operators can quickly program the cobots for specific welding tasks, allowing staff to focus on other critical activities and increasing overall productivity.

Enhanced Speed and Safety: With industry-leading operating speeds and advanced safety features, DenaliWeld cobots ensure efficient production while maintaining a safe working environment.

Cost-Effective Investment: Offering affordable automation without compromising quality, DenaliWeld cobots deliver a high return on investment by reducing labor costs and increasing output.

Maximum Operational Flexibility: Seamlessly switch between manual operation and automated welding, allowing for efficient workflow management and adaptability to changing production needs.

Independently developed welding robots and welding control systems

DenaliWeld independently developed welding robots and welding control systems, which are jointly tested to ensure optimal performance, reliability, and functionality to meet evolving user needs. We offer a wide selection of collaborative robot models, creating flexible and efficient automation solutions.

- Full compatibility: Compatible with air- and water-cooled DenaliWeld models, allowing for flexible cross-platform integration.

- Proven Performance: Rigorous joint testing ensures higher precision, smoother operation, and consistent results in real-world welding applications.

Seamless Transition

DenaliWeld collaborative robotic welding solutions are designed for maximum flexibility, featuring handheld welding torches that enable a smooth transition between manual and automated welding.

- Quick Switching Mechanism: The laser welding machine is equipped with a manual/automatic switching button, allowing operators to easily toggle between handheld and robotic welding modes.

- Enhanced Flexibility: This dual-functionality design supports customized workflows, enabling users to adapt quickly to changing production demands while maintaining precision and efficiency.

Simple and Easy to Use

DenaliWeld collaborative robotic welding systems are engineered for simplicity, offering quick integration and hassle-free setup across a variety of robotic welding applications.

- Fast Installation: Designed for rapid deployment, allowing users to get up and running quicklywith minimal downtime.

- User-Friendly Interface: Intuitive controls ensure easy operation, making it accessible for both experienced professionalsand new operators.

- Versatile Application: Compatible with various robotic welding tasks, delivering consistent performance across different production environments.

Technical Parameters

| Technical parameters | Item | Denbot5-910 | Denbot10-1300 | Denbot16-2000 |

| Robot body | Maximum Load | 5kg (11.2lb) | 10kg (22.05lb) | 16kg (35.27lb) |

| Number of axes | 6 | 6 | 6 | |

| Maximum speed at the end | 3.6m/s (11.81ft/s) | 3.8m/s (12.47ft/s) | 3.5m/s (11.48ft/s) | |

| Maximum linear velocity at the end | 1.5m/s (4.92ft/s) | 1.5m/s (4.92ft/s) | 1.8m/s (5.91ft/s) | |

| Effective working radius | 917mm (36.1in) | 1300mm (51.18in) | 2000mm (78.74in) | |

| Repeatability | ±0.02mm | |||

| Power consumption | ≈200w | |||

| Installation method | Ground based、Inverted type、cantilever type | |||

| IP Grade | IP54/65 | |||

| Ambient temperature | '-10℃ - 50℃ | |||

| Storage temperature | '-40℃ - 55℃ | |||

| End I/O port | 2DI、2DO、EtherCAT、RS485 | |||

| Robot packaging size | 698x588x450mm (27.48x23.15x17.72in) | 958x508x516mm (37.72x20x20.31in) | 1465x516x472mm (57.68x20.31x18.58in) | |

| Net weight | 22kg (48.5lb) | 37.8kg (83.33lb) | 60kg (132.28lb) | |

| Control cabinet | Input power supply | '100-240VAC 47-63HZ 10A | '100-240VAC 47-63HZ 10A | 220-240VAC 47 -63Hz 10A/100-200VAC 47-63HZ 16A |

| IP Grade | IP44 | IP44 | IP44 | |

| Communication interface | TCP/IP,Modbus/TCP,Profinet(Slave From),Ehernet/IP(Slave From),CAN,RS485 | |||

| IO interface | 16DI, 16DO (PNP,24V/Max 500mA) Configurable 8DI/8DO | |||

| Size | 410x306x292mm (16.14x12.05x11.5in) | |||

| Weight | 13.6kg (29.98lb) | 13.6kg (29.98lb) | 13.8kg (30.42lb) | |

| FlexPendant | External dimensions | 295x225x45mm(Excluding grip handle) | ||

| IP Grade | IP54 | IP54 | IP54 | |

| Screen size | 10.4 in | |||

| Screen resolution | 800*600@60HZ | |||

| Weight | 1.3kg (2.87lb) |

Shipping

For shipping and shipping return questions on DENALIWELD products purchased directly from DENALIWELD, or for warranty return shipping questions, please contact us by one of the methods listed below.

Order Status

Get In Touch

Office:224-802-8809

Operating Hours:

Monday through Friday: 9AM to 6PM PST

Reviews

There are no reviews yet.